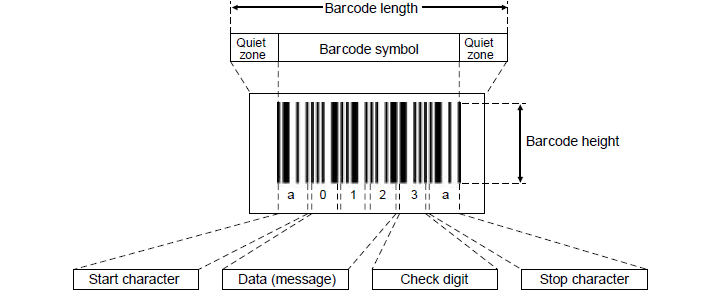

See full list on barcodefaq.com. Barcode basics: Understanding barcodes and product codes Today, we are going to cover the barcode basics regarding barcodes and product codes. We’ll begin with an example for produce. Product information for produce is regulated by the International Federation for Produce Standards. Barcode Basics 24 March 2020 Why We Should Focus on Our Partnerships During Times Like These Label Printers, 100 Words or Less, Barcode Basics 12 March 2020. Barcodes are measured by the width of the narrow bar and are recorded in mils, or 1/1000 inch. A 15 Mil bar code, for instance, has a narrow bar that is 15/1000 inches wide. Further, 'quiet zones,' or blank spaces to the left and right of barcode symbols, are included to insure the barcode can be read. The 'Barcode Information & Tips' site offers information on the standards and basic principles relating to barcodes and 2D codes. This site is managed by KEYENCE CORP. Barcode Types (EAN, CODE 39, ITF, CODABAR, CODE 128)|Basics of Barcodes|'Barcode Information & Tips' Reference Site for Barcode Standards and Reading Know-How KEYENCE.

January 5th 2021 16:00:00 PM

If you are shipping products from your manufacturing or distribution warehouse, you are already familiar with barcodes, but how much do you really understand about them? They are the kind of everyday thing that works in the background of your business, aren’t they? Everything runs well until the day comes that you have to make decisions about upgrading your barcode scanning hardware or printers. At that point, you may find yourself at a loss knowing where to turn.

Put your mind at rest. We will walk you through the barcoding basics and explain what barcoding is, how it benefits your business, and how to choose a barcode scanner.

Are you looking for immediate advice about your barcoding hardware and printing options? No problem! Contact us online or call (330) 645-9959 to arrange a consultation with a Scanco Solutions Expert.

What is Barcoding?

Barcoding is an identification process used by many industries to identify, track, and manage products. They are commonly used on such varied items as shipping labels, foodstuffs, library books, pharmaceuticals, and construction materials.

Barcodes are also used in manufacturing, production, and distribution. They are used to track assets and equipment in a warehouse, as well as managing raw materials held in inventory. Barcodes bring accuracy and efficiency to modern products and services.

Why are Barcodes Used in Business?

If you had to design a method for tracking products and materials, the barcode is a logical choice. Here are some reasons why they are used by so many types of businesses worldwide:

- Barcodes provide readings quickly.

One of your team members can use a barcode reader to capture a barcode label of 12 characters in about the same time it takes someone to type two characters on a keyboard.

- Barcodes are incredibly accurate.

Even the most experienced, accurate keyboard operator is not 100% accurate in their work. For every 1,000 characters typed, there is an average of 10 keyboarding errors. With a barcode reader, there is approximately one error in every 36 trillion characters.

- They are versatile.

A barcode can be printed onto almost any material, which makes them an excellent choice for tracking inventory.

- Barcode systems are cost-effective.

Barcode systems save time and prevent errors, which creates value for your business. Barcode labels are inexpensive and can be read by several types of barcode readers. They can be created and printed on demand when you need shipping labels.

- The system is very user friendly.

Your team will be able to learn how to operate barcode scanners in as little as 15 minutes. You won’t be faced with lengthy training sessions or a lot of downtime when you are ready to implement the system.

How Barcodes Improve your Operations

How can barcode data collection benefit your warehouse or distribution center? The following are a few examples:

- Simplifies Shipping and Receiving

You may receive shipments from your suppliers that include barcodes or you may need to print and apply your own labels for these items when they arrive at your facility. The shipping labels contain the following information:

- The type of item

- Purchase Order number

- The name of the supplier

- The lot number

- The date the item was delivered

This information is used to create a receiving/purchasing record for the item. With it, the item’s history can be easily traced. If the item is shipped out to a customer, a new barcode label will need to be generated.

Barcode label software can connect to your Sage ERP database to create labels quickly and as often as needed. Once a shipment has left the warehouse, the barcode labels make tracking packages easy.

- Monitors Fixed and Circulating Company Assets

Barcodes were originally used to keep track of fixed assets. Barcode labels were attached to large pieces of equipment, machinery, computers, office furniture, and fixtures. They were used to maintain records of the assets the business owned, determining when to perform regular maintenance, and for calculating depreciation.

- Streamlines Inventory Management

Barcodes are an invaluable part of inventory management. They keep track of raw materials, parts, supplies, and products your business buys, stocks for resale, and consumes. When you and your team know exactly what you have in stock at any time, you can avoid overstocks and not run out of in-demand items at crucial times. This data helps to even out your cash flow in purchasing and boosts your sales revenue.

Choose the Right Barcode Scanner for Your Business

If you are interested in buying barcode scanners for your company, there are a few things you need to consider before you make a final decision. The more carefully you do your “homework” first, the more likely you will be pleased with the model you decide to purchase.

- What is the Barcode Scanner’s IP Rating?

The IP (Internal Protection) rating indicates how well a barcode scanner can be expected to hold up against dust, solid objects, and water in its casing. Barcode scanners may also be rated for vibration protection and whether they will still perform after being dropped onto a concrete or a steel surface.

- Will the Scanner be Used in Extreme Temperatures?

If your team will be using barcode scanners in cold storage units or other environments where the equipment is expected to operate in extreme temperatures, low temperatures can be particularly taxing on your scanning equipment. When non-optimized equipment is used in cold conditions over a long time, exposure to the cold temperatures can cause housings and screens to become splintery. Condensation inside the units can lead to corrosion. As a result, the internal components may short-circuit and fail to operate.

- Is Portability an Important Feature?

When you picture your team taking the barcode scanner directly to the items being scanned, your best bet is to choose a scanner that is lightweight, easy to carry, and portable. A cordless scanner operates on a battery and includes a base for charging the scanner and transmitting data. This type of scanner also gives you the convenience of WiFi communication.

If you would like to use a scanner attached to your computer system, check your computer’s ports. You will need to check for an available USB, PS2, or serial port to attach the scanner. If no compatible port is available, an adapter may be used to connect your computer to a port. If you are using a barcode reader that is attached to a computer, it does not need recharging.

- Is the Barcode Scanner Compatible With the Software and the Barcodes You are Using?

Before you decide a barcode scanner for your business, you’ll want to ensure that it is compatible with your warehouse management software.

You’ll also want to make sure the scanner works with the type of barcodes you use. Most businesses use either 1D (one-dimensional) or 2D (two-dimensional) barcodes. The linear barcodes which are made up of straight lines only are examples of 1D barcodes. A 2D barcode is shaped like a square or a rectangle and contains small, individual dots.

Scanco’s Barcode Solutions Let You Scan Away Concerns About Automation

Scanco has been helping business owners find the right solutions in barcoding automation for more than a quarter-century. We will find the best fit for your business and can provide barcode scanning hardware and label printers, along with compatible software to help your company become more efficient.

For more information, click here to see to Scanco’s recorded webinar on this topic.

We are also ready to help you personally. Contact us online or call (330) 645-9959 to set up a consultation with a Scanco Solutions Expert.

Barcode basics: Understanding barcodes and product codes

Today, we are going to cover the barcode basics regarding barcodes and product codes. We’ll begin with an example for produce. Product information for produce is regulated by the International Federation for Produce Standards. Most other food items and consumer goods that you can find around the house or workplace use product code standards created by the GS1 organization.

DISCOVER BARCODING

“The GS1 System provides for the use of unambiguous numbers to identify goods, services, assets, and locations worldwide. These numbers can be represented in barcodes to enable their electronic reading wherever required in business processes. The system is designed to overcome the limitations of using company, organisation, or sector specific coding systems, and to make trading much more efficient and responsive to customers.”[1]

Here is a side-by-side comparison of the barcode labels usually found on produce (left) and packaged goods (right):

As you can see, the produce sticker contains an image of its origin (the yellow semicircular image), barcode (the thin and thick black lines), and a product code (4046). You can read more information on produce stickers here.

In contrast, the packaged item’s product identifier is a U.P.C. barcode: barcode lines (the thin and thick black lines) with a product code (the series of numbers under the barcode)[2]. The string of numbers underneath the barcode lines make up the item’s Global Trade Item Number®, or GTIN®[1]. Packages and shipments, as well as warehouse containers and units, utilize a separate system for standardized identifying numbers created by the GS1.[3]

The GTIN is a standardized method of assigning a universally recognizable product code to an item, which is helpful for consumers, distributors, manufacturers, and anyone involved in the supply chain. Per the GS1, the GTIN:

“…uniquely identifies trade items at all item and package levels, thus ensuring that they are always identified correctly anywhere in the world. Each trade item that is different from another is allocated a separate, unique GTIN.”[1]

Barcode Basics App

Here is an example of a GTIN from GS1’s website[4]:

Most items that can be bought by consumers include a GTIN-12 or a GTIN-13 to accompany the barcode; the numbers following simply refer to the number of digits in the GTIN[5]. These are the items you would most likely buy from a grocery store or retail store.

A GTIN is comprised of three elements[6]:

- A U.P.C. company prefix

- Item reference number

- Check digit

In order to receive a U.P.C. company prefix, a company must apply to GS1 and have one assigned to them.[5] From there, the company will assign GTINs to all items they manufacture using their designated U.P.C. company prefix. The company prefix is unique to each company and is a way to identify the company that claims ownership of a product[7].

However, the GS1 states…

“Note that since GS1 member companies can manufacture products anywhere in the world, GS1 prefixes do not identify the country of origin for a given product.”[8]

So purely going off of the first digits you see on a product label to determine where it was manufactured can be misleading for many reasons, including:

– U.S. companies are assigned a company prefix starting with the number ‘0’[7]. However, those companies may not include the ‘0’ in the beginning of their product label GTIN numbers.

– As noted by the GS1, a U.S. GS1 registered company may manufacture their products in another country or other countries.

So as a consumer, the best way to know where a product was manufactured is to look for a “Made In…” label. Additionally, you can find out what company the product is registered under using GS1’s handy GTIN search tool.

Barcode basics: How a barcode inventory management system is used in business

So we learned about barcodes and GTINs from a consumer standpoint, but how are they actually utilized by businesses?

As far as the U.P.C. barcode lines, the barcodes can be scanned to maximize productivity and accuracy in the warehouse or store.

For instance, barcodes can be scanned to:

- receive inventory in the warehouse or store

- pick items and fulfill orders

- conduct inventory counts and verify inventory

GTINs provide a way for businesses to identify a product. This is in conjunction to other identifiers such as:

- SKUs

- serial and lot numbers

- internal product ID

- product description

These identifiers can be associated with the related product in an inventory management system. Having multiple product IDs and descriptions are helpful when looking up an item in a database.

Barcode Basics Pdf

Barcode inventory management can be a useful tool, especially for those businesses that handle many products, have a warehouse or warehouses, or simply want to reduce the amount of time spent on inventory management while increasing accuracy. To learn more about barcodes and barcoding, check out our barcoding and mobile page for how you can utilize barcodes in your business or warehouse.

References

Barcode Basics App

1. GS1’s ‘An Introduction to the Global Trade Item Number (GTIN)’, 2.GS1’s ‘About the GS1 Company Prefix’, 3.GS1’s ‘GS1 Standards’, 4.GS1’s ‘Search by GTIN’ tool, 5.GS1’s ‘GS1 General Specifications’, 6.GS1’s ‘Create Your Product or Location Identification’, 7.GS1’s ‘Get a Licensed GS1 Company Prefix’, 8. GS1’s ‘GS1 Company Prefix’ listings

Get started today!

Gs1 Barcode Basics

Learn more about Acctivate’s flexible mobile barcoding capabilities and other powerful business tools. Try Acctivate for free or call us at 817-870-1311.